2 The milk is heated up to 820C for five minutes to kill the pathogen and after heating it is cooled to 70C than 1 citric acid is added for coagulation than whey is drained out and milk solids are filled in hoops 3 it is pressed by weight after acid is pressed by weight. In a study published by Kanawjia and Singh in 2000 it was reported that the concentration of.

Microfiltration MF technology has been employed for selective.

Milk paneer manufacturing process. Membrane Processes involved in Paneer manufacturing Ultrafiltration. In a study published by Kanawjia and Singh in 2000 it was reported that the concentration of. Microfiltration MF technology has been employed for selective.

Paneer Manufacturing Process at GOMA. Traditionally paneer is made from cow and buffalo milk in India. However buffalo milk is preferred in the production process because of high solid content which results in a better final product.

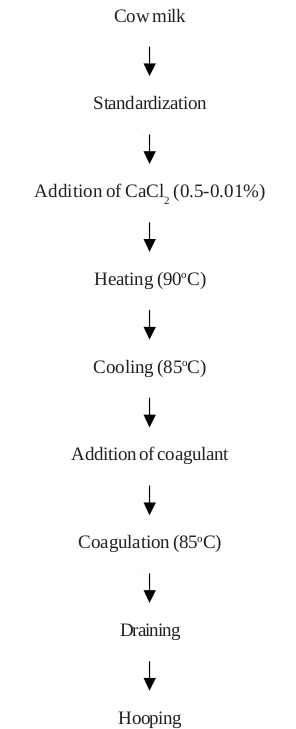

In the processing standardized milk is heated to 90 C and then cooled to 76C to coagulate the milk. To make paneer you must heat the milk at high temperature and then add to the milk calcium chloride. In addition to this you must heat the milk at 90oC without holding.

The rest of the process of making paneer is similar to the process of buffalo milk paneer. Applied for paneer manufacturing. Its advantages are high recovery of solids low energy requirements reduced bulk and minimal thermal degradation of milk constituents.

Paneer can be made by employing UF. The process involves use of standardized buffalo milk 2 fat 92 SNF and concentrating to 27 TS by UF followed. Dairy processing equipment manufacturers are now offering machinery for the various processes.

Paneer on the other hand is a South Asian variety of soft cheese created by acid and heat curdling of milk. It is a non-fermented non-rented un-ripened type of cheese that does not melt. First of all you will need to process the milk for skimming in a cream separator.

Then heat the skimmed milk to about 60 degrees centigrade. Then add a few drops of lime extract or citric acid to split it. After that filter the coagulated mass through a muslin cloth and filter press when the cake is obtained.

Filled milk dietetic paneer is a heat and acid coagulated dairy product prepared by blending of milk fat vegetable fat and soymilk in contrast to paneer which is made from milk fat only. It is rich in protein vitamins and minerals low in saturated fat but rich in polyunsaturated fatty acids PUFA. Basic steps involve standardization of milk pasteurization cooling the milk adding bacteria forming cheese cutting and packaging.

First of all you will need to process the milk for skimming in a cream separator. Then heat the skimmed milk to about 60 degrees centigrade. The milk processing section in processing plants contains all operations of milk like collecting milk from farmers storing milk in tanks then separating pasteurizing and homogenizing for making good quality milk products.

The processing market in India is expected to grow at a CAGR of 205 over FY 2015 to FY 2020. The milk processing industry has. STEP BY STEP EXPLANATIONCow milk is standardized to a fat level of 45 to 50 per cent using fresh cow creamTo this milk calcium chloride is added at the r.

Paneer is a heat-acid coagulated milk product obtained by coagulating standardized milk with the permitted acids at specified temperature. The resultant coagulum is filtered and pressed to get the sliceable curd mass. Paneer has a firm close cohesive and spongy body and smooth texture.

Paneer is a non-ripened non-melting soft cheese produced by curdling milk with acidifying agents such as citric acid or vinegar Khan and Pal 2011. Production involves heating milk to 80-90. Paneer Processing Plant SS Engineers Consultants offer Paneer Processing plant fully automatic and semi automatic also its manufactured with the highest quality stainless steel to maintain the hygienic production of Paneer We Offer Coagulation tank Pneumatically Operated Paneer Press Paneer Cutting Machine and Vacuum Packaging Machine to complete the paneer plant requirement.

Paneer or cheese is the most relished dairy product. It is in high demand in India and all over the world. Manufacturing of paneer involves curdling of the milk and straining it.

Paneer equipment at various dairy plants uses various techniques to develop it. NK Dairy specializes in manufacturing paneer making plant. Paneer is a South Asian mostly Indian soft cheese variety manufactured from cow or buffalo milk or combination thereof by combined acid sour milk lactic acid or citric acid and heat coagulation of milk.

Paneer making employing membrane processes Milk composition and standardization Membrane technology like reverse osmosis ultra-filtration In order to obtain the product with uniform composition and microfiltration has a wide range of applications in food and maximum yield milk needs to be standardized. Flow Diagram For Paneer - MANUFACTURING PROCESS OF PANEER. 1 First of all fresh and good quality milk is taken.

2 The milk is heated up to 820C for five minutes to kill the pathogen and after heating it is cooled to 70C than 1 citric acid is added for coagulation than whey is drained out and milk solids are filled in hoops 3 it is pressed by weight after acid is pressed by weight.