As far back as 1965 a. This is done via a coring process on the existing operating pipeline without any interruptions to the flow of medium and system.

Cold tap is used for system that carry flammable medium.

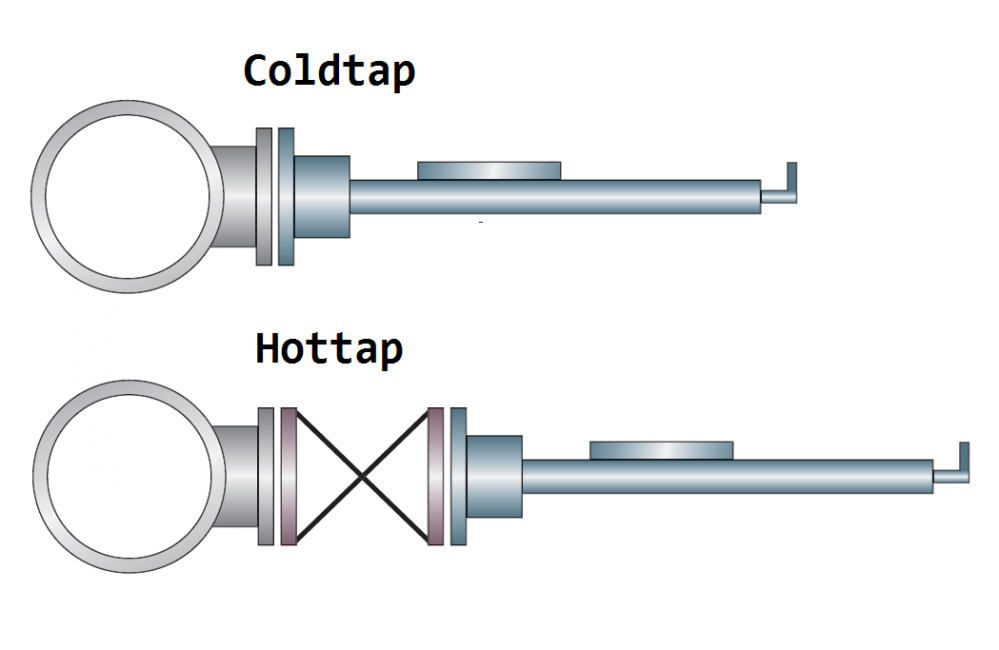

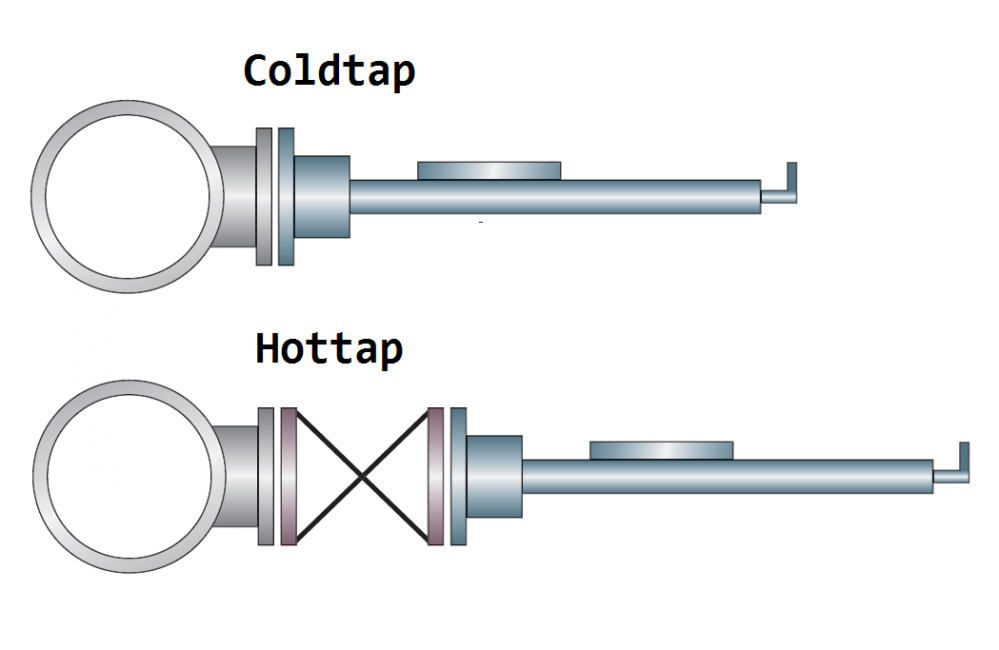

Cold tapping vs hot tapping. Hot tap Cold tap is a method of employing an under-pressured drilling machine to provide a branch off pipeline from existing main pipe. This is done via a coring process on the existing operating pipeline without any interruptions to the flow of medium and system. Cold tap is used for system that carry flammable medium.

Cold tap prevents ignition especially fuel line. Hot and Cold Tapping also refer to pressure tapping is one of the technique to attach a branch connection to existing piping or pressure vessels while the system is in services. Hot Cold Tapping allow adding connection without depressurization or disruption of process operations.

Hot Cold Tapping. Hot Cold Tapping or Under Pressure drilling is the method of attaching a branch connection to existing pipelines or vessels or any other process equipment while the existing system is under pressure. This method employs a Tapping Machine and a full bore valve and either a nozzle or a full encirclement fitting Split Tee welded.

Hot tapping by my definition is welding onto and cutting into a live line while it remains in service. Cold tapping is joining into a line taken out of service either by spool replacement between two flanges with the added branch as you describe or cutting a tee or Olet into the line by welding. Hot Tapping and Cold Tapping.

Hot Tapping and Cold Tapping for all types of pipes during operation with material Stainless steel or Carbon steel with thickness up to 18 mm under pressure up to 1440 psi. And temperature up to 280 C. We also have the technical specialized team that is capable of doing these types of jobs with high perfection.

Hot Tapping Cold Tapping of compressed air flow meter installation points. If playback doesnt begin shortly try restarting your. Hot taps can be performed on many different types of systems such as steel stainless steel and cast iron.

Systems containing wastewater drinking water steam oil gas and even sour gas can be safely modified without costly downtime. Tapping size up to 12 through 6 Coring. So when hot water was introduced the logical conclusion about where to put this new tap was simply on the opposite side of the cold water tap the left.

So the common sense answer is that the hot tap is on the left because people are mostly right handed and the cold tap is used the most often. Hot Taps or Hot Tapping is the ability to safely tie into a pressurized system by drilling or cutting while it is on stream and under pressure. Tapping fittings like Weldolet Reinforced Branch or Split Tee.

Split Tees often to be used. Hot tapping is an alternative technique that allows the connection to be made without shutting down the system and venting gas to the atmosphere. Hot tapping is also referred to as line tapping pressure tapping pressure cutting and side cutting.

The process involves attaching branch connections and cutting holes into the operating. Mixer taps especially early ones do not generally work well with a big difference in supply pressure between hot and cold with a simple mixer design the high pressure of the cold water restricts the flow of the hot water into the tap. Hot tapping or pressure tapping is the method of making a connection to existing piping or pressure vessels without the interrupting or emptying of that section of pipe or vessel.

This means that a pipe or tank can continue to be in operation whilst maintenance or modifications are being done to it. The cold water taps in the bathroom may be supplied from a storage tank in the loft so the quality may not be as good as that from the kitchen tap which comes directly from the mains. Do not drink water from hot water taps as it may contain high levels of copper.

Hydratights hot and cold tapping service provides the solution to plant and pipeline modifications without the need to decommission thus reducing plant downtime. Hot tapping of pipelines under operating pressure Hydratights Hot Tapping and Cold Tapping service allows you to meet deadlines safely and with minimum disruption to production. Cold tapping allows work to be performed on a section of pipeline without flooding of the line and subsequent dewatering and drying.

The operation is performed on a pipeline where the internal pressure has been pipeline where the internal pressure has been equalized to slightly above the hydrostatic pressure of the seawater. It should also be understood the Forming taps run better at speeds 1-12 to 2 times faster than a cut tap and require much more attention to lubrication of the tool as friction between the tap and the workpiece can create problems with generated heat and torque forces imposed on the entire set-up. Water bylaws prevented hot and cold water being mixed because water that had been sitting in a tank in the loft was not deemed safe to drink he said.

As far back as 1965 a. My taps are hot left cold right. To turn them on I have to turn the hot tap clockwise and the cold tap anti-clockwise.

Oct 21 2011 2 Anticlockwise off or maybe not now Im confused doing funny twisty motion with hand trying to visualise it. In plumbing it refers to attaching an existing pressurized main supply line to a new system of supply or to a new residence or commercial building where there is no convenient way to shut off the main water supply pressure ahead of time.